Refrigeration spotlight

Get ready for cooling directive change

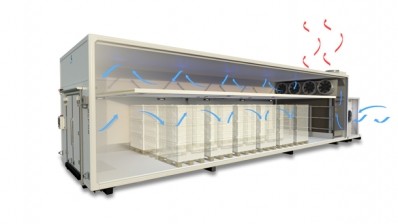

The directive governs all energy-related products, including chillers and industrial coolers, and is set to impose strict new minimum energy performance standards for industrial process cooling systems.

The new benchmark for an industrial process chiller will be its seasonal energy performance ratio (SEPR). Minimum SEPRs are calculated as the ratio between the annual refrigeration demand and its annual electricity consumption.

The legislative changes will outline the new minimum requirements, with products most likely to impact manufacturers falling into Lot 1 (refrigeration and freezing equipment, including medium and low-temperature process chillers and condensing units) and Lot 21 (high-temperature process chillers and condensing units).

With process cooling and refrigeration systems currently typically accounting for 60% of a plant’s total lifecycle cost, inefficient chillers can contribute to highly inflated utility bills.

“The upcoming changes to the Ecodesign Directive outline stringent new minimum SEPRs for process cooling equipment, which many manufacturers may not be aware of,” says Richard Metcalfe, sales director at ICS Cool Energy.

Contact ICS Cool Energy for more information.