News

The British Crisp Co launches ‘world’s first’ fully recyclable crisp bag

Developed in partnership with packaging manufacturer EvoPak, the new bag is made from paper and Hyrdopol – a biodegradable and compostable polymer – covered in a thin layer of vacuum deposited aluminium to keep the crisps fresh.

This new construction allows the bags to be recycled in the same way as newspaper or cardboard and can be picked up by kerbside collection.

A new range of crisps packaged in the new bags will be launching in the coming months across shops, pubs, hotel and coffee shops across the UK in three of The British Crisp CO’s most popular flavours – Sea Salt, Salt & Vinegar and Cheese & Onion.

Fully recyclable

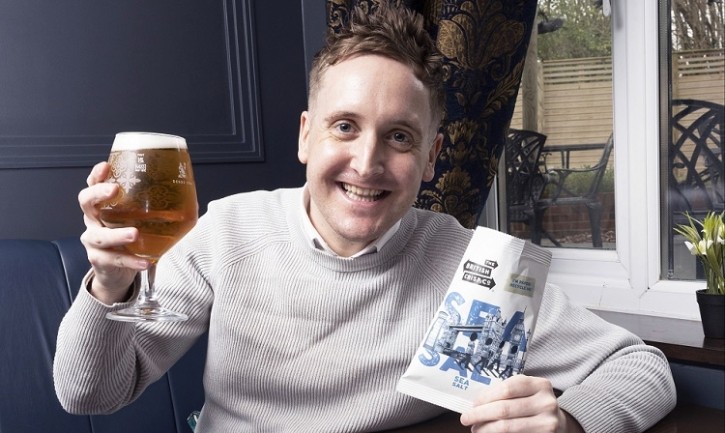

Tom Lock, founder of The British Crisp Co (pictured), said: “We believe in more than just great taste and high-quality ingredients – we’re passionate about sustainability. That’s why we are delighted to be the world’s first crisp brand to bring to market a fully recyclable paper pack.

“In addition, we make our crisps on a UK farm that not only grows its own potatoes but is powered by renewable energy. So, we like to say that our crisps don’t just taste good, they do good too.”

The packaging has also been OPRL accredited, which means the bags can display the green ‘Recycle’ logo, accompanied by the words ‘I’m paper, recycle me’.

‘Significant milestone’

Mark Lapping, chief executive officer at Aquapak, added: “Today’s launch marks a significant milestone for Aquapak and our Hydropol technology, which can be commercialised at scale.

“Producers now have a viable, environmentally safe, and recyclable alternative that enables full fibre recovery in standard paper recycling and does not form microplastics in the process.”

Meanwhile, infant and children’s food manufacturer Ella’s Kitchen has partnered with data and environmental impact platform Foodsteps in a bid to slash its carbon emissions by half.

Starting with an independent assessment of life cycle emissions across the brand’s product portfolio and supply chain, the partnership will enable Ella’s Kitchen to accurately measure the environmental impact of 210 products.